Description

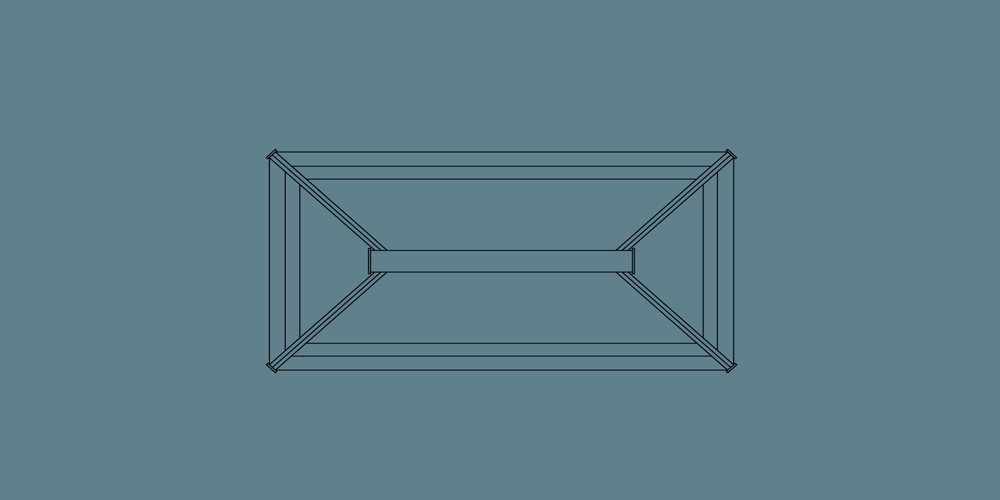

- 1000mm x 2000mm external size

- Only 4 pieces of glazing

- minimal sections for sleek, clean, sharp and crisp lines

- typical rafter / ridge sections only 40mm wide

- intelligently detailed

- maintenance-free

- able to maximise the use of light and space in your home

- engineered to give stylish ambience to any interior space

Delivery included and delivered in 20 working days!

Technical

Specification

Scope

This specification defines the basic, construction, materials and performance of the Atlas aluminium patent glazing

roof system.

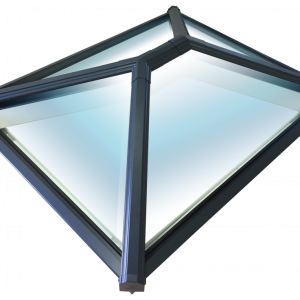

Design Concept

The profiles in this range have been designed solely for roof glazing. The standard pitch is 25 degrees and provides a complete thermally broken structure when complete. The British Board of

Agrement tested the roof system and have indicated that the roof will have a life expectancy of at least 25 years.

Materials

Framework consists of a high tensile aluminium section (Alloy 6063 T6 to BS 1474 :1987) box section 40mm wide

by 68mm, 81mm and 97mm in depth, giving the options of profiles to suit larger spans. The thermal break comes

in the form of a PVCu extension adaptor connected to the main rafter box section. This section is designed to receive

an aluminium exterior cover cap.

Aluminium exterior cover caps can be powdered coated to any Ral colour, providing a durable and attractive roof finish.

Please note, it is possible to have an inner framework finished in a different Ral colour to that which is outside. All

Atlas roofs are produced in line with BS EN ISO 9001 :2000 quality control conditions and are BBA approved to

market leading standards.

Finishes

All aluminium is polyester powder coated with 80-100 microns of paint to BS 6496. Full Ral colour range is available.

Anodising is to BS 3987 and finishing is conducted under BS EN 9002 :1994 quality control standards.

Construction

Construction consists of main sloping rafters, fixed to the ridge via load bearing brackets tested by Queens

University, Belfast (20 Kn). Rafters are carried directly by a adjustable ringbeam. Standard hip and valley sections

are connected in the same manor. All roofs are pre assembled in the Atlas factory before delivery. All joints shall be

sealed against water entry as per Atlas’s installation manual. Glazing is secured by a snap on exterior cover cap

and pressure plate, providing a continuous pressure seal against the glazing.

(Uplift tested to 1320 pascals of pressure)

Performances

Atlas roof’s have been engineered to comply with severe weather ratings.(Wind loads 1.32 Kn/m2 and snow loads

1.0 kn/m2). The structure when finished using standard planitherm double glazing units will have a thermal U value of

approximately 1.3 W/m2k. BBA test results indicate that the U value for Atlas roof rafter is 1.5 W/m2k.

Secondary drainage channels have been designed into the PVCu thermal break. This allows drainage channels

to run over the bottom ringbeam, providing a unique, but effective way of draining the roof system. (Water test

pressure 300 pascals)

Glazing

All double glazing is Kite marked toughened glass which is 5 times stronger than ordinary glass (BS 6206 :1981

with a Class 0 fire rating) .All Atlas glazing has continuous spacer bars and are dual sealed (BS 5713 ). Double

glazing or triple glazed units rest on a co extruded EPDM gasket and are held into position by a pressure plate and

aluminium exterior cover cap.

Units should be installed in accordance with BS 6262 :1982, BS 8000, Part 7 : 1990, the GGF glazing manual or

European equivalent.

Download Spec Sheet

Download Spec Sheet